| Business contact | |

|---|---|

| Contacts | Manager Shao |

| Telephone | 13203839989 |

1. Equipment introduction

The needleless electrospinning is realized by replacing the needle electrode with a metal linear electrode. Small size, light weight, high integration, free movement, convenient and flexible for scientific research activities.

2. Equipment advantages

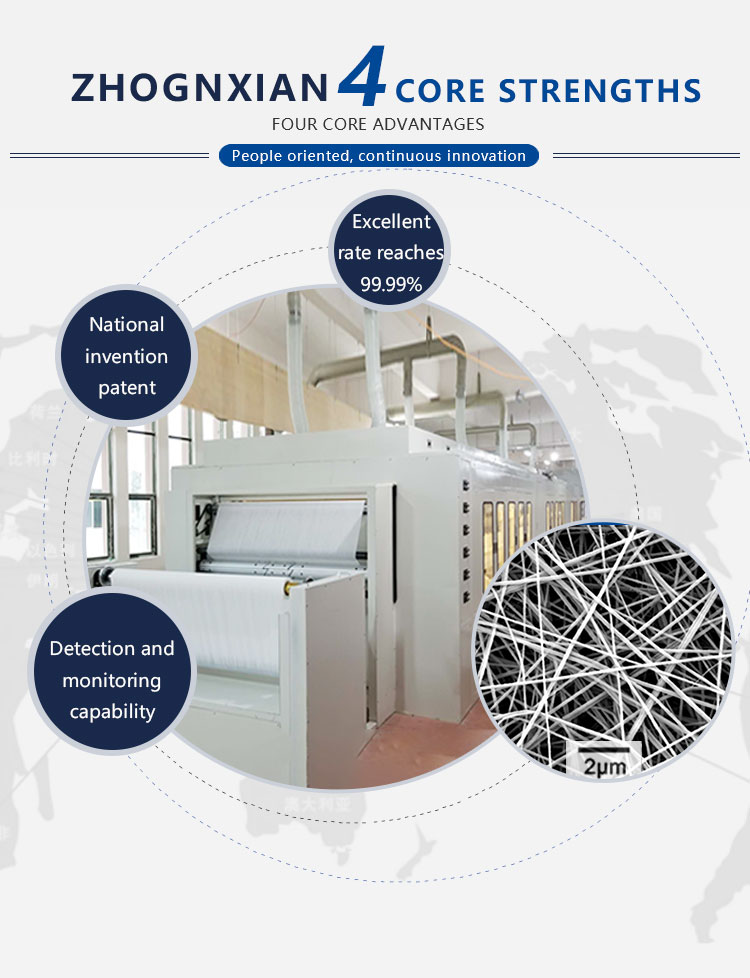

Good product uniformity and high spinning efficiency: needleless electrostatic spinning without needle arrangement, and with uniform electric field distribution and good fiber uniformity. The equipment has high production efficiency and low energy consumption. The maximum width of the product is about 600 mm.

It is easy to maintain and clean: needleless electrospinning is not easy to block and maintenance is more convenient.

3. Equipment application fields

It is suitable for the preparation of air filter materials, medical dressing, battery separator, mask paper, etc.

[中文]

[中文]